玻璃態轉換溫度, Glas transition temperature

玻璃態轉換溫度(TG) 是膠水變脆時的溫度。應用溫度顯然要高于膠水的玻璃態轉換溫度 (如 可重復揭開的袋子存儲在冰箱里,可以防止袋子的重新閉合)

The glass transition temperature (TG) is the temperature at which the adhesive becomes brittle. It is important that the application temperature is distinctly above the TG of the adhesive (e.g. resealable bags that are stored in the fridge or freezer as it can prevent a safe reclosure of the bag).

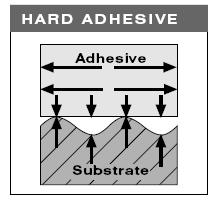

硬膠, Hard adhesive

通常用來描述高內聚力的壓敏膠帶。

優點(相比軟膠):

高的保持力

承受較高的重量

好的耐溫性

較少的溢邊

有助于提高模切性能

缺點:

低初粘性和粘接力

需要更高的壓力

不適合粗糙表面

Term usually used to characterize highly cohesive PSA tapes.

Advantages (compared to soft adhesives):

higher holding power withstands

higher sustained loads good temperature resistance

less edge picking

improved die cuttability

Disadvantages:

low initial tack and adhesion;

requires higher contact pressure

not suited for rough surfaces

熱熔壓敏膠, Hot melt pressure-sensitive adhesive

可以不使用溶劑或水涂布的壓敏膠水的類型。現在合成橡膠和丙烯酸的壓敏膠可以做熱熔涂布。

Types of pressure sensitive adhesive that can be coated without use of solvents or water. Today PSA tapes based on synthetic rubber as well as acrylics are available for hot melt coating.

耐濕性, Humidity resistance

水氣甚至是濕氣可以影響膠水的性能。尤其應用于有水或者潮濕的環境中,膠水會吸潮,將導致粘接效果降低。這樣的影響尤其會發生在水性丙烯酸膠水,此類膠水不適合在潮濕的環境中使用。

Moisture or even humidity can affect the performance of an adhesive. Especially if applied under wet or very humid conditions the adhesive absorbs the humidity, which leads to reduced adhesion performance. This effect occurs especially with water-based acrylics, which should not be used under those conditions.

總體來說壓敏膠具有耐濕性,可以抵抗接觸到的潮濕的空氣或甚至是水而不會對粘接效果有負面影響。

In general a PSA tape is humidity resistant when it resists contact with humid air or even water without negative effects on the adhesion properties

所有的丙烯酸具有很好的耐濕性。潮濕可以影響紙質離型紙并導致膠帶表面起泡。基本上,塑料薄膜離型紙相比紙質的尺寸穩定。

All acrylics have a good humidity resistance. Humidity can damage paper liners and lead to “bubbles” on the surface of the tape. Basically, filmic liners are more dimensionally stable than paper ones.

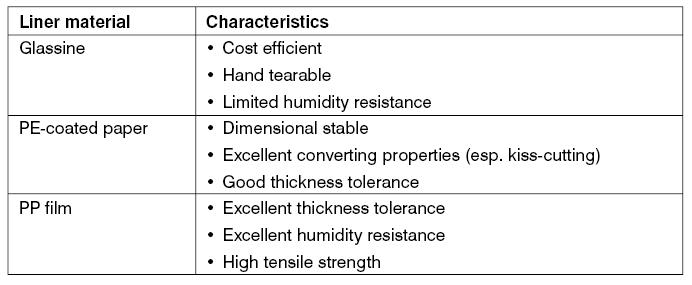

離型紙, liner

不容易粘接的材料覆蓋在大多數的雙面膠帶和一些單面膠帶上,保護膠帶不會自身粘在一起。離型紙在操作/制程和存儲中被用于保護層。最常用的離型紙的類型有:

1. 紙質離型紙(如 格拉辛紙, PE涂層紙, 粘土涂層紙)

2. 塑料薄膜離型紙(如 聚丙烯,聚酯,聚乙烯) 硅被用作離型劑避免離型紙與膠水粘接在一起。

Anti-adhesive material which covers the adhesive on almost all d/s and some s/s tapes and prevents the adhesive from sticking to itself. The liner is used as a protection aid during handling/processing and storage. Most commonly used liner types are

1. Paper liners (e.g. Glassine paper, PE-coated paper, Clay-coated paper)

2. Film liners (e.g. PP, PET, PE) Silicone is used as release system to avoid adhesion between liner material and adhesive.

轉移, migration

當兩個表面接觸在一起,一種組分從一個表面轉移到另一個表面長期的分子運動。轉移可能發生在膠帶與被應用的表面之間。某些塑料薄膜(如PVC)包含增塑劑,可能轉移到膠帶膠水上,引發膠水變軟。其他的成分例如發泡劑,硫化劑,應用于柔軟的封條上的抗老化劑可以轉移到膠帶上危害粘接效果。

The molecular movement over a long period of time of an ingredient from one surface to another when both are in contact. Migration may occur between tape components and the surface to which applied. Some plastic films (e.g. PVC) contain plasticizers which are apt to migrate into the tape adhesive, causing the adhesive to soften. Other ingredients like foaming, vulcanisation, age-resistant agents used for flexible seals migrate into the tape and can compromise the bond.

非極性材料, Non-polar substrates

因為低表面能而難以粘接的表面。較低的表面能,較低的分子吸引力。典型的材料是聚烯烴,如聚丙烯和聚乙烯,聚苯烯,乙烯-乙烯乙酯共聚物和很多粉末噴涂表面。通過表面處理(如光暈處理),極性可以被改變至較高的表面能,提高粘接效果。使用底涂劑也可以作為粘接助劑。

Critical surfaces to adhere to due to low surface energy. The lower the surface energy the lower the molecular attraction to the adhesive (adhesion). Typical materials are polyolefins such as PP and PE, but also PS, EVA and many powder painted surfaces. By surface pretreatment (e.g. corona treatment) the polarity can be modified to achieve higher surface energy and improved adhesion. Use of primers will also act as adhesion promoters.

揮發性, Outgassing

化學成分從膠水中揮發出來(如單體殘余物, 溶劑等)尤其在高溫情況下。化學殘余物可能出現的影響在汽車,航空和電子行業中經常是一個問題。

Amount of chemical ingredients evaporating from adhesives (e. g. monomer residues, solvents, etc.) especially under elevated temperature conditions. Often a concern in the Automotive, Aerospace and Electronics industries, where chemical residues could affect e. g. electric circuits.

極性材料, Polar substrates

因為高的表面能而相對容易粘接的表面。在這些被粘物上,在膠水和被粘物中間高的分子吸引力會增加粘接強度。最常見的材料有PET, PC, PVC, ABS,鋼板,鋁,玻璃等。

Uncritical surfaces to adhere to due to high surface energy. On these substrates the high molecular attraction between adhesive and substrate leads to increased adhesion. Most common materials are PET, PC, PVC, ABS, steel, aluminum, glass etc.

底涂劑, Primer

一種涂層先于膠水使用前應用于表面(如基材或者被粘物表面),提高基材和膠水或者膠帶和被粘物表面之間的粘接效果。

A coating applied to a surface (e. g. backing or a substrate) prior to the application of an adhesive, improving bond performance between backing and adhesive or between tape and substrate